Turbulator Products

Partner with us for your turbulator manufacturing needs. We specialize in creating turbulators with diverse geometries, dimensions, and materials, providing optimal efficiency solutions for various heat exchanger systems.

We offer four primary turbulator designs that can be customized for both small and large production quantities. Our turbulators are tailored to match the specific tube sizes, flow regimes, and temperatures of the application. This ensures optimal heat transfer efficiency and pressure drop characteristics. Additionally, we strongly recommend practical testing to assess the impact of turbulators on the overall efficiency and pressure drop within the specific application.

Read More Below

↓

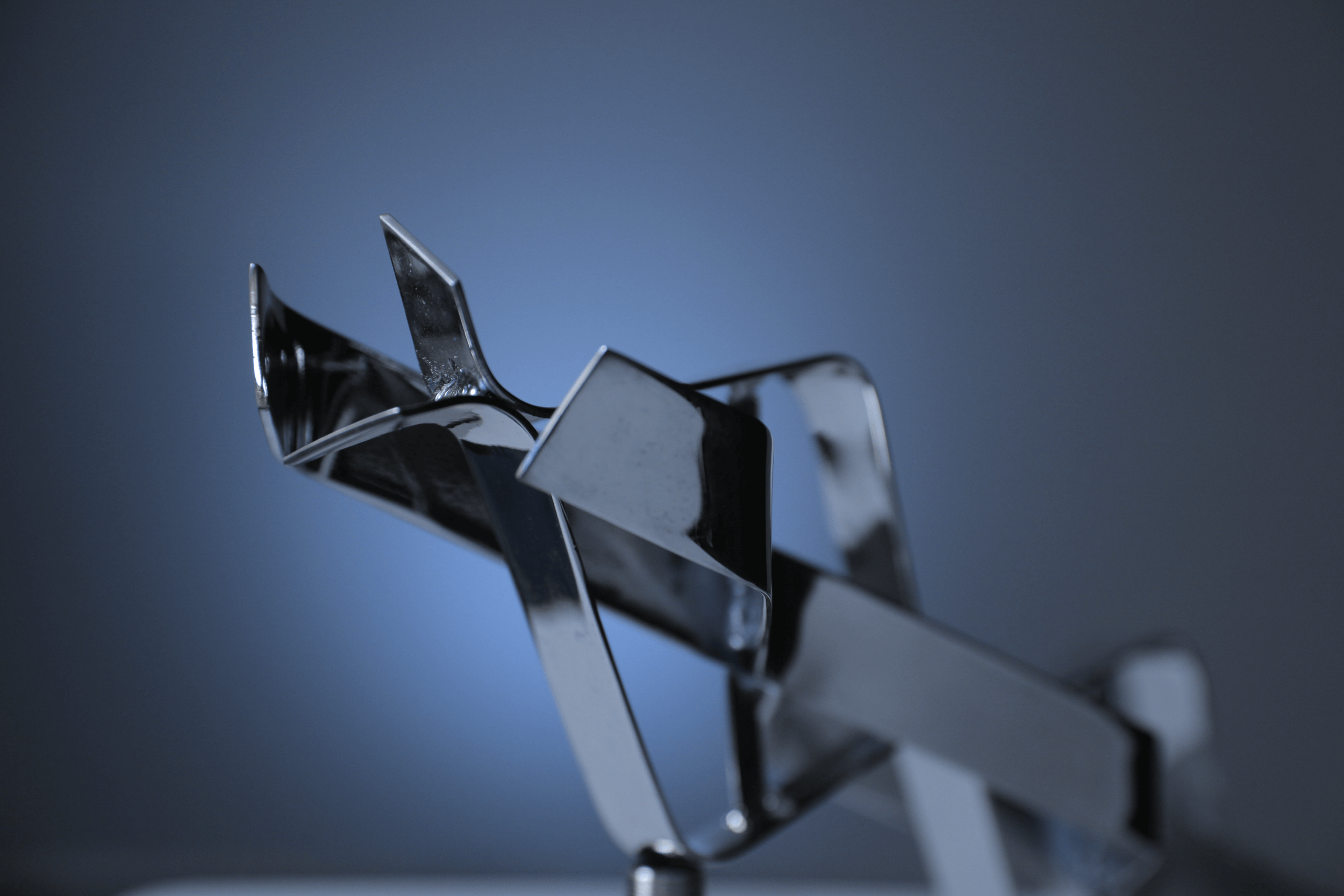

Angular

-

Firetube Boilers

Cast Iron Sectional Boilers

Radiant Heaters

Vertical Tube Boilers

-

Material:

Carbon steel, aluminized steel and various grades of stainless steel

Minimum Tube Outside Diameter:

1 inch

Maximum Tube Outside Diameter:

36 inch

Minimum/Maximum Length:

Limited ONLY by shipping feasibility

-

Angular “Brock” Turbulators are small baffles, fabricated using a flat strip of steel with bends that are angled and spaced in such a way that they cause turbulence in the flow of combustion gases through tubes. This spreads the hot gases evenly over the heating surfaces and makes heat exchange more efficient. Turbulators are sized to match the ID of the tubes. Length, width, material type, and quantity will vary according to the heat exchange equipment in which they are used. Used in new and existing equipment.

Twisted Tape

-

Firetube Boilers

Shell and Tube Heat Exchangers

Any Tubular Heat Exchange Equipment

-

Materials:

Carbon Steel, Stainless Steel or Copper. If we can source the alloy, we can fabricate it.

Width:

.150” – 4” – For larger tubes, multiple band options available

Length:

Limited ONLY by shipping feasibility

-

Twisted Tape Turbulators are static mixers, fabricated using flat strips of steel that are formed into spiral or helix. Inside tubes, they induce a swirling and mixing action of tube side fluid causing higher near wall velocities, eliminating thermal boundary layers, and breaking up laminar flow regimes. Twisted Tapes are sized to closely match the ID of the tubes. Length, width, and material type will vary according to the heat exchange equipment in which they are used. Used in new and existing equipment.

Multiband

-

Firetube Boilers

Indirect Fired Heaters

Line Heaters

Dehydration Units

Water Bath Heaters

Reboilers

Cast Iron Sectional Boilers

Immersion/Vat Heaters

U-Tube Process Heaters

-

Material:

Typically carbon steel and stainless steel. However, if we can source the alloy we can fabricate it

Minimum Tube Outside Diameter:

4 inch

Maximum Tube Outside Diameter:

36 inch

Minimum/Maximum Length:

Limited ONLY by shipping feasibility

-

Multiband Turbulators are 2-4 turbulators arranged, angled, and spaced in such a way that they cause turbulence in the flow of combustion gases through tubes. This spreads the hot gases evenly over the heating surfaces and makes heat exchange more efficient. Turbulators are sized to match the ID of the tubes. Length, width, material type, and quantity will vary according to the heat exchange equipment in which they are used. Used in new and existing equipment.

Coiled Rod

-

Firetube Boilers

Radiant Heaters

Tubular Heat Exchangers

-

Materials:

Carbon Steel, Various Grades of Stainless Steel, Copper Brass and More

Outside Diameter:

.25” – 10”

Wire Diameter:

.008”- .625”

End Options:

Open or Closed; Ground or Not Ground

Length:

Limited ONLY by shipping feasibility

-

Coiled Rod Turbulators are coiled springs, fabricated in such a way that the coil OD closely matches the tube ID. Inside tubes, they induce a swirling and mixing action of tube side gases causing high near wall velocities, eliminating boundary layers providing the greatest measure of conductive heat transfer. Length and material type will vary according to the heat exchange equipment in which they are used. Used in new and existing equipment and occasionally conjunction with other types of turbulators.